Steam Traps, Steam Pipes, Valves CM

Condition Monitoring of Steam Traps, Steam Transmission Systems`

Combination of NDT techniques is what needed to conduct condition monitoring of Steam Traps and Steam Transmission Systems. Thermography and Ultrasound inspections are the techniques with which we can monitor steam traps, steam transmission system effectively.

Combination of NDT techniques is what needed to conduct condition monitoring of Steam Traps and Steam Transmission Systems. Thermography and Ultrasound inspections are the techniques with which we can monitor steam traps, steam transmission system effectively.

|

|

|

|

|

Product: Condition Monitoring of Steam Traps and Steam Transmission Systems

Process: Quarterly or bimonthly assessment of Steam Traps along with transmission systems, in the following way;

Efficient Steam Trap Failure Detection through combination of Techniques

When it comes to steam traps, people often ignore them. Losses can include not only wasted energy but also replacement of damaged equipment and misuse of man-hours. It is not uncommon to discover system losses in the hundreds of thousands of currency.

Fortunately, a vigilant steam management (Proactive Maintenance) system that includes a program for steam trap Condition Monitoring can avert much of these potential losses. A steam trap CM creates a window into a steam system. Once our expert can see what is going on, can suggest corrective action. Cheaper corrective actions can add substantially to a company's bottom line as "found money”.

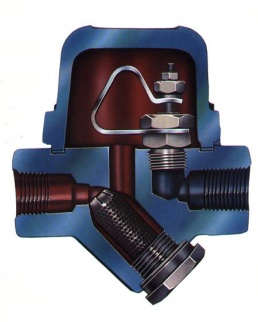

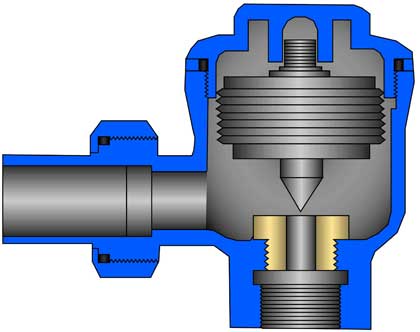

Steam traps can fail in an open or closed position. A trap that "fails open" allows steam to escape in to the condensate system. A trap that “fail closed” prevents condensate from being discharged, which slowly turns to carbonic acid and corrodes the metal.

-

Visual Inspection

In a visual inspection, the expert will check that the discharge valve is functioning. This requires venting live stream to atmosphere and can pose safety issues. Because it opens the closed portion of the system, it is not a 100% reliable test. Visual inspection is important because the trained expert can look for potential problems in engineering and design that can lead to trap failure.

Certain visual signs such as the lack of any condensate discharge or extremely large quantities of steam leaking out of a trap may indicate the need for trap repair. Of course, a visual assessment is limited to reviewing open systems. When recovering condensate in a closed piping system, for instance, the piping will prevent performing visual diagnosis. Installing a sight glass at the trap’s outlet may help provide a visual indication in some instances.

Traps can also be externally inspected for pinhole, connection joint, and gasket leaks. In most cases, unless a condition problem can be clearly determined visually, testing traps by sound and temperature, and in some cases by thermography, will then be required to provide a correct diagnosis.

Certain visual signs such as the lack of any condensate discharge or extremely large quantities of steam leaking out of a trap may indicate the need for trap repair. Of course, a visual assessment is limited to reviewing open systems. When recovering condensate in a closed piping system, for instance, the piping will prevent performing visual diagnosis. Installing a sight glass at the trap’s outlet may help provide a visual indication in some instances.

Traps can also be externally inspected for pinhole, connection joint, and gasket leaks. In most cases, unless a condition problem can be clearly determined visually, testing traps by sound and temperature, and in some cases by thermography, will then be required to provide a correct diagnosis.

-

Thermal Mapping of Steam Trap

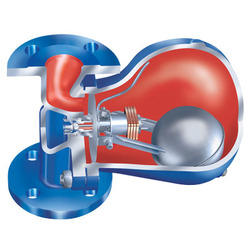

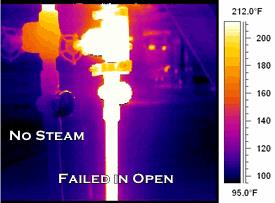

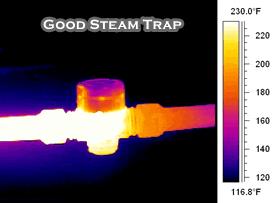

Important method for CM of traps is with thermal mapping through IR camera. Upstream and downstream temperature checks can reveal failed open/ chocked traps. However, variables such as backpressure in the system can make this check less accurate. Thermal inspections are useful for identifying heat loss, overloads, and pressure build-ups. Relying on IR inspection alone does not capture the complete picture.

In general, if a thermal image shows a high inlet temperature and a low outlet temperature (< 212 °F or 100 °C), that indicates that the trap is functioning correctly. If the inlet temperature is significantly less than the system temperature, steam is not getting to the trap. Look for an upstream problem—a closed valve, pipe blockage, etc. If, both the inlet and outlet temperatures are same, then the trap probably has failed-open and is “blowing steam” into the condensate line. This keeps the system operating but with significant energy loss. Low inlet and outlet temperatures indicate that the trap has failed-closed and condensate is filling the trap and the inlet line.

Using thermal imager while steam system is operating to scan help us to find anomalies in Steam transmission lines for blockages, including closed valves, and underground steam lines for leaks too.

|

|

In general, if a thermal image shows a high inlet temperature and a low outlet temperature (< 212 °F or 100 °C), that indicates that the trap is functioning correctly. If the inlet temperature is significantly less than the system temperature, steam is not getting to the trap. Look for an upstream problem—a closed valve, pipe blockage, etc. If, both the inlet and outlet temperatures are same, then the trap probably has failed-open and is “blowing steam” into the condensate line. This keeps the system operating but with significant energy loss. Low inlet and outlet temperatures indicate that the trap has failed-closed and condensate is filling the trap and the inlet line.

Using thermal imager while steam system is operating to scan help us to find anomalies in Steam transmission lines for blockages, including closed valves, and underground steam lines for leaks too.

-

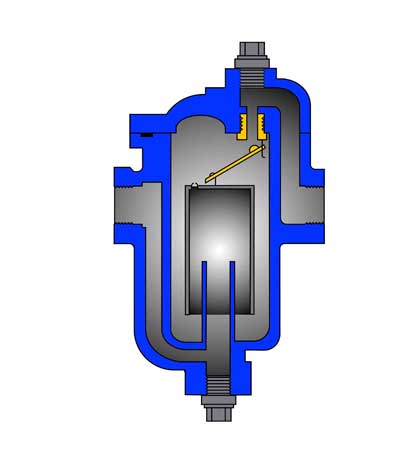

Ultrasound Measurement of Steam Trap

Ultrasonic testing ties all other inspections together and make sure nothing is missing. Steam trap inspection benefits highly of ultrasound technology: traps in pre-failure phase will start generating revealing ultrasound signals. Our instrument, SDT 270 detects these signals and translates them into audible and analyzable sound, which gives the expert a truly representative inside view of the trap.

|

|